Although recent California winters have been wetter than usual, the default condition of the state is one of water scarcity – due to geography, climate, and a burgeoning human population. 85% of Californians depend on groundwater for at least some of their water needs. For residents in a particular Water District south of Santa Cruz, that figure is 100%.

It’s vital that the District’s groundwater wells perform at peak efficiency, to control costs in this challenging economic environment, and, as responsible public servants, to shrink the carbon footprint and energy consumption of groundwater production.

To continue providing safe, reliable water to its 40,000 customers, the District elected to have a new well drilled. A highly respected southwest hydrogeology firm provided the well design, and consulting services throughout the construction and development process. An experienced drilling contractor with 30 rigs and 70 employees won the drilling contract.

Well #2 was situated on a small plot of land in a crowded residential neighborhood. To reduce the noise impact of operations, the driller constructed an impressive series of sound-baffling walls.

The well was drilled to a total depth of 540’, with a diameter of 16”.

Based on e-logs showing the disposition of water-bearing strata in the formation, stainless steel wire-wrapped screens were placed at 257-307, and 340-530, a total of 240’ of perforated area. Static water level in the well was 182’.

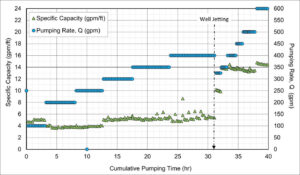

The contractor drilled and developed the well using their standard practices that have proven successful for decades, but performance was suboptimal. This was due at least in part to shallow submergence limiting the effectiveness of airlifting. The well was producing approximately 400 gpm, with 73’ of drawdown, for a Specific Capacity of 5.5 gal/ft/minute – less than targeted output, with considerably less than desired efficiency.

Having worked successfully with WellJet® on prior new well development and rehabilitation projects, the consulting firm suggested adding its patented process of high-pressure hydrojetting to the development menu. Although jetting has been around for decades, WellJet’s unique combination of proprietary tooling, delivery mechanism, expertise and experience has enabled it to deliver superior results in over a thousand wells around the world from Hawaii to the Middle East.

The majority of wells treated by WellJet® only require a single pass of high-pressure jetting through the perforation zone in order to positively impact yield. In this case, because of the documented difficulties affecting well output and efficiency, WellJet® recommended two passes to ensure sufficient energy was generated downhole to maximize success.

After frustrating equipment maintenance delays, WellJet® mobilized to the site, laid out, and began jetting. The plan was to execute two complete runs through the perforation zones, the first at 18,500 psi, and the second at 17,500 psi, with a retrieval rate of 1.0’/minute.

On the first day, the lower 60’ were jetted twice, and the upper 180’ jetted once. WellJet® equipment was removed from the well, and the bottom tagged at 518’ – a total of 22’ of fill material. As a general rule, the accumulation of substantial fill after jetting indicates that the WellJet® process has successfully delivered energy through the well screen into the gravel pack and near-wellbore formation, dislodging harmful deposits that impede free water flow.

The second day of jetting saw the WellJet® pump break down before the 2nd run of jetting was completed – not a happy situation! The decision was made to conclude the WellJet® portion of development at this point, and to move on with further development steps provided by the drilling contractor.

Naturally, despite the positive indications from the amount of fill, all were concerned that WellJet® hadn’t completed its 2nd run. Had WellJet® done enough to positively affect well performance?

After further development by the driller, the well was test pumped – with excellent results:

The positive outcome pleased all parties – and demonstrated the value of dedicated collaboration among the design/consulting team, the drilling and development expertise of the contractor, and the unique power of WellJet®. As the consultant said, “I call that a huge success!”

The Water District was also impressed, saying: “WellJet® was so good we are mandating it for all our new wells.”

Music to the ears of all of us at WellJet®!