Three years of planning and preparation bore fruit in the late winter of 2022-2023, as WellJet® mobilized personnel and equipment from California, across the fruited plain, to New England.

Specifically, New Haven, Connecticut. Birthplace of the Knights of Columbus, Yale University, and Frank Pepe’s legendary pizzeria. Founded in 1638, New Haven is also home to the South Central Connecticut Regional Water Authority (RWA), a nonprofit corporation that provides 45 million gallons a day of water and related services to 430,000 consumers in the region. Staffed by experts known for both their experience and innovation, RWA consistently pursues a Best Practices approach to operating and maintaining the wells that serve the community.

WellJet® was invited to participate in a multi-well rehabilitation project for RWA. The targets were three older wells, two of which had been drilled in the 1960s (since fitted with stainless steel liners, tending to reduce performance), and the third that was situated close to the Housatonic River and suffered from biofouling and high concentrations of manganese. All three wells had suffered significant declines in production and efficiency and were considered difficult to restore.

WellJet® (US Patent No. 8,312,930 B1) has built its global reputation as the world’s leading practitioner of high-pressure hydrojetting for water well development and rehabilitation by improving flow rates and efficiency in just such “difficult to restore” wells. Over the past decade, WellJet® has developed and rehabilitated more than a thousand wells throughout California, Arizona, Nevada, Colorado, Utah, Texas, Hawaii and the Middle East. No other tool or process is capable of matching WellJet’s ability to generate energy downhole to remove encrustation, open clogged perforations, and break down harmful deposits in the filter zone and near-wellbore formation that impede free water flow. This unique ability is especially useful in lined or sleeved wells.

The rehabilitation team consisted of RWA, SB Church (driller/pump company), HydroPressure Cleaning, Inc. (HPC/WellJet®), and WSP engineering and professional services. Groundwater Science, an independent consulting firm based in Ohio, was present to observe the process and evaluate the results.

Communication and collaboration among the team proved invaluable, as the scope of work changed based on discoveries and data collected in the field while the rehabilitations were under way.

The wells were all contained inside structures, with the difficult access addressed by the use of HPC’s purpose-built quadropod to make possible the WellJet® high-pressure hydrojetting process.

Per the Groundwater Science Report:

NSG #2

“Well challenges: The older NSG wells were far into their performance decline curves, and how the lining helped them operationally is open to question, probably to deal with sanding. This made them more difficult to rehabilitate, as the inner screens and filter packs took up energy that would go into the formation. Clogging was attributed to iron biofouling, according to file reports, which included BART culturing.

“The Seymour wellfield had long been troublesome due to very high manganese, including likely deposits of MnIV oxides identifiable in drilling logs, not surprising in a highly organic sand and gravel.”

The general rehabilitation procedure involved pump removal, downhole video, sodium hypochlorite treatment, high-pressure hydrojetting by WellJet®, cleanout surge-and-airlift, additional jetting, and then physical and chemical redevelopment.

The liners in NSG-2 and NSG-1 (which had just been installed) demanded high pressure (15,000-18,000 psi) and multiple passes with the jetting tool, to generate energy beyond the screens and gravel packs, into the near-wellbore formation to break down harmful deposits impeding free water flow. Seymour #5, a more delicate well with no gravel pack below 83’, required different tooling and a single pass at lower pressure (5,000 psi).

SB Church performed the non-jetting services, under the supervision of RWA personnel, with consulting from WSP.

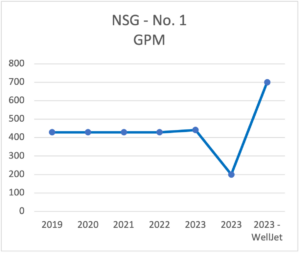

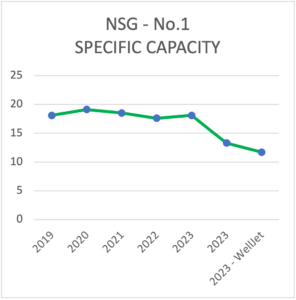

North Sleeping Giant Well #1

Drill date: 1965

Total Depth: 157’

Diameter: 18”

Construction: steel casing, original Everdur (brass)

screen 130-157 ft (27 ft screen), now with stainless

steel wire-wound liner & filter pack

Static Water Level: 27’

Design demand: 1,600 gpm

Max Pump Capacity: 1,250 gpm (many years since)

Most recent specific capacity: 13.33 @ 200 2/22/23

North Sleeping Giant Well #2

Drill date: 1967

Total Depth: 104’

Diameter: 16”

Construction: steel casing, Everdur (brass) screen,

stainless steel insert screen, filter packed: Old: 15 ft

screened, 20 ft inside.

Static Water Level: 26’

Design demand: 1,000 gpm

Max Pump Capacity: 764 gpm (long time since)

Most recent specific capacity: 16.2 @ 486 gpm

Seymour Well #5 (different aquifer, along Housatonic River, high manganese)

Drill date: 1981

Total Depth: 127’

Diameter: 16”

Construction: steel casing, stainless steel wire-wound screen, part filter pack, part (lower) natural pack

Static Water Level: 18’

Screen type + zone: screened 72-127’ (55 ft total screen, multiple slot sizes, partially filter-packed)

Design demand: 800 gpm Max Pump Capacity: 725 gpm (long time ago) Most recent specific capacity: 10.2 @ 260 gpm.

Having equipment and personnel available from all teams enabled WellJet® to jet one well, then move to another well and jet it, while fill was removed from the previously jetted well. WellJet® could thereafter return to the prior well to perform additional jetting – a procedure that was optimal given the short lengths of perforated area in each well.

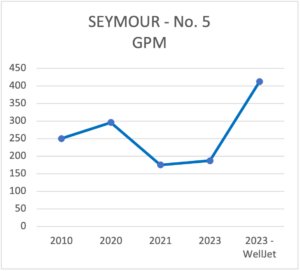

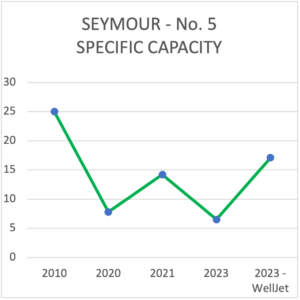

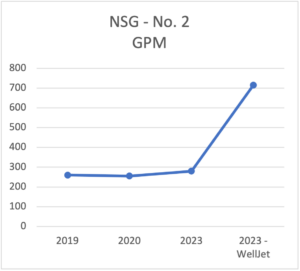

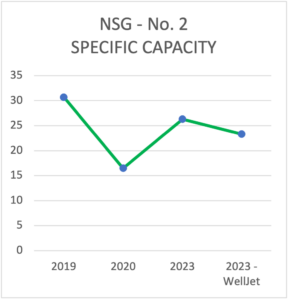

The WellJet® process was dramatically successful on two of the three wells (NSG #2 and Seymour #5). Results were less impressive on NSG #1, although the recent installation of the liner prevented a true apples-to-apples comparison, as all prior performance data was gathered before the liner had been installed.

From GWS Report on Seymour #5:

“… the Q/s values at 314 gpm and above have not been seen for a very long time (possible Q/s = 25 gpm/ft at 250 gpm in 2010).”

From GWS Report on NSG #2:

“In the case of NSG No. 2/2N, it has been many years since Q/s values calculated for Q = 427 and 715 gpm in the March 14, 2023 step test have been observed. This is a successful result considering the age of the well, restrictions and impairments. Note that, although drawdown in the field data was stabilized at 30 min. and 427 gpm, the higher Q/s at 427 gpm vs. that at 280 gpm indicates that the well continued to develop.”

When considering this positive outcome on NSG #2, Jim Hill, Director of Operations at SCCRWA, said: “If we’d known about WellJet 10 years ago, we could have saved the trouble and expense of drilling a new replacement well.”

From GWS Report on NSG #1:

“The step-test (April 27, 2023) results from NSG No. 1 were not as favorable as for NSG No. 2/2N in calculated specific capacity, but exhibited the classic pattern of a well still developing, specific capacities (Q/s) rising as flow rate Q is increased: The Q/s at the lower Q is lower than during the brief airlift test in February, and much lower than the step-test results in November 2022… which followed the normal, stabilized pattern of lower Q/s at rising Q. The third high-pressure pass may have compacted fines drawn into the vicinity of the screen, and these are being developed out. Also, it is not unusual for a well in a severely plugged state to exhibit a drop in specific capacities as fines are drawn in, before further development brings better results.”

When asked if it was worth it to bring WellJet® all the way across the country to help rehabilitate RWA wells, Jim Hill said: “Let’s do it again!”